Glaze: 1/8" Acrylic

Beams: T5 Aluminum

Span Length: 10'0"

Width: 4'2"

Centers: 25"

Load: 50.7 lb/sq/ft

Load/Rafter: 105.7 lb/lin. ft.

Deflection (inches) Vert. = 5.08 in.

Deflection (inches) Horiz. = 0.64 in.

Note: Original sheet thickness was 1/8", today we utilize 3/16" as standard glaze thickness. All center to center Rafter dimensions are now 26 1/8".

Aluminum structural members: Are all extruded T-5 6063 architectural grade aluminum alloy.

Exterior Finish: Factory raw, White/Brown spray enamel, or electrostatic powder coat custom color.

Nylon Plugs: Proprietary design - White/Brown fastening members.

Glaze Seal: "Santoprene" cup seal - 4 per full Rafter/Barcap length, 2 upper & 2 lower.

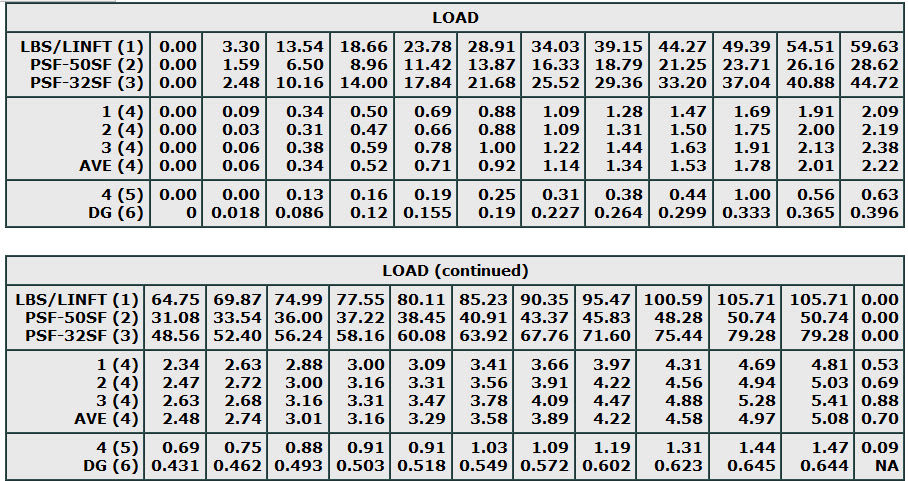

Engineering and Load Test Results

Load Test Results

The test results are listed in Table 1. Loading was continued until it was observed that deflection occured under constant load. For this test assembly it was undesirable to apply load to destruction thus when creep deflection was observed, unloading was initiated. The test assembly and loading are illustrated above. For convenience the test results have been summarized below Subject: Results for the full-scale load test performed on the 10 ft. span.

Notes:

1) T5 architectural grade aluminium rafter 1½ inches depth

2) Nominal span: 10 feet

3 ) Test assembly constructed with three rafters 25 inches on centre

- Load calculated for a 50 sq. ft. area (i.e. that area supported by three rafters)

** - Load on per beam basis as shown in sketch

TABLE 1

LOAD TEST DEFLECTION DATA

1. Load calculated as lbs/lineal ft/beam

2. Load calculated as lbs/ft² on a 50 ft² area

3. Load measured as lbs/ft on a 32 ft² area

4. Midspan certical deflection gauges

5. Vertical deflection gauge at curve

6 .Horizontal deflection gauge at curve

Left to Right

• Angle for under and over glaze @ the Terminating front face 2(1/16" x 1.5" x 1.75")

• 1/8" x 1" x 1' Angle - used at all corners

• "Base and Ridge": used to connect to structure @ roof and foundation areas. Note: the black and white Nylon connection plugs. Main rafter slip over these plugs and locked via a screw.

Short Section of Rafter

Rafter + Barcap which is screwed into the rafter every 11"

Note: the seals, (4 in total) - 2 each per aluminum barcap & rafter system, plus PVC screw cap cover.

Barcap

Basically 1.5" width x 1.2" total thickness depth.

Note: Upper profiles receives "PVC Screw Cap" & lower profile receives the cup seals (2 per Barcap length), plus pre-drilled holes every 11" along length for securing barcap and glaze, to rafter segments during construction.

Rafter

Both left and right upper shoulders support the glazing sheet with the 2 full length seals sitting under the glaze in respective slots. The center channel is to receive the screw from the Barcap that will squeeze or lock down the glaze, yet will still allow the sheet to remain alive under pressure for the required sheet expansion and contraction.

Note: The underside will be able to be slipped together to built a double or triple rafter as required due to some spans.

Rafter centers are 24" to 26 1/8"

[ Centers are dependent on sheet width from manufacturer ( 48" to 52 1/4") ]

Note: Cross brace at mid span and wooden support posts + beam

Interior view of twin wall Clear polycarbonate glaze and white rafter/barcap

Note: Full length seal above and below glaze.

Interior view of twin wall Bronze Tint polycarbonate glaze and white rafter/barcap.

Bronze Tint twin wall polycarbonate glaze

Note: Curved front face support posts.

| PRODUCTS | TYPE | RESISTANCE |

|---|---|---|

| CHEMICALS | Acetone | Non-Resistant |

| CHEMICALS | Ammonia | Non-Resistant |

| CHEMICALS | Carbon Dioxide, moist | Resistant |

| CHEMICALS | Citric Acid 10% | Resistant |

| CHEMICALS | Ethyl Alcohol, 96% pure | Resistant |

| CHEMICALS | Hydrochloric Acid, 20% | Resistant |

| CHEMICALS | Isopropyl Alcohol | Conditionally Resistant |

| CHEMICALS | Kerosene | Resistant |

| CHEMICALS | Ozone | Resistant |

| CHEMICALS | Petroleum | Conditionally Resistant |

| CHEMICALS | Propane Gas | Resistant |

| CHEMICALS | Sulphur Dioxide | Conditionally Resistant |

| CHEMICALS | Sulphuric acid, 50% | Resistant |

| DETERGENTS | Ajax Cleanser | Resistant |

| DETERGENTS | Laundry Soap | Resistant |

| DETERGENTS | Soft Soap | Resistant |

| ADHESIVES | All-purpose Glue | Conditionally Resistant |

| ADHESIVES | Gypsum | Resistant |

| ADHESIVES | Insulating Tape | Resistant |

| ADHESIVES | Putty | Resistant |

| ADHESIVES | Rubber | Resistant |

| LUBRICATING OILS | Automatic Switch Grease | Resistant |

| LUBRICATING OILS | Silicone Oils | Resistant |

| LUBRICATING OILS | Brake Fluid | Non-Resistant |

| LUBRICATING OILS | Cable Insulating Oil lG 1402 | Resistant |

| LUBRICATING OILS | Cable Insulating Oil KH 190 | Resistant |

| LUBRICATING OILS | Diesel Oil | Conditionally Resistant |

| LUBRICATING OILS | Drilling Oil | Non-Resistant |

| LUBRICATING OILS | Fish Oil | Resistant |

| LUBRICATING OILS | Heating Oil | Conditionally Resistant |

| LUBRICATING OILS | Jet Fuel [JP4] | Conditionally Resistant |

| LUBRICATING OILS | Paraffin | Resistant |

| LUBRICATING OILS | Silicone Fluid | Resistant |

| LUBRICATING OILS | Turpentine | Conditionally Resistant |

| LUBRICATING OILS | Varnish | Conditionally Resistant |

| VARIOUS | Battery Acid | Conditionally Resistant |

| VARIOUS | Cement | Resistant |

| VARIOUS | Floor Polish | Resistant |

| VARIOUS | Natural Rubber | Resistant |

| VARIOUS | Ocean Water | Resistant |

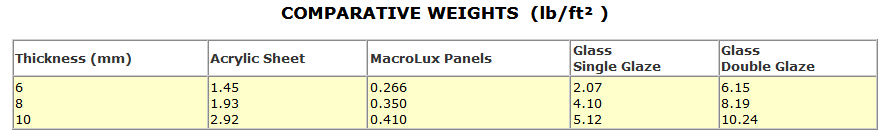

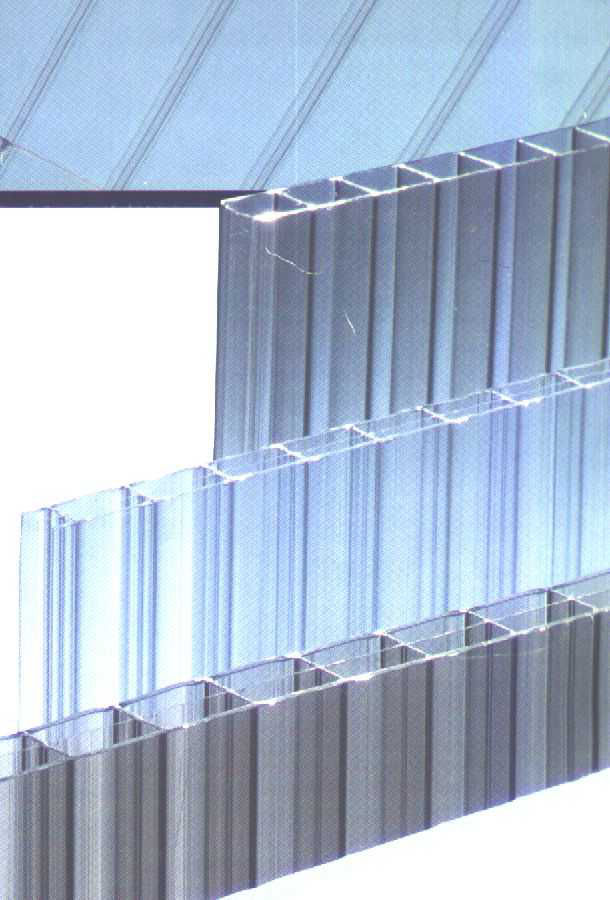

( 3/8" Twin Wall Example)

Weight = 0.41 lbs./ft.2

CLEAR 80 %

BRONZE 50 %

WHITE 62 %

U-Factor (BTU/hr.-ft.2 F)

0.54

R-Value

1.79

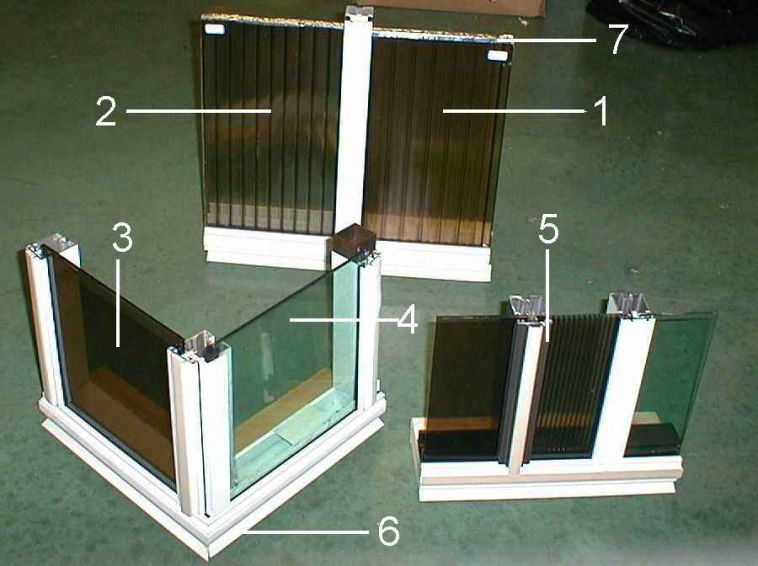

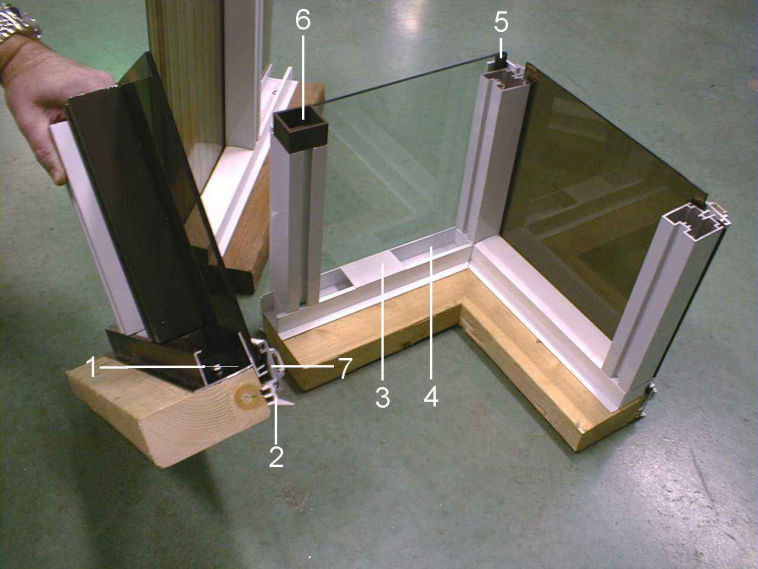

. Acrylic Corner Unit

. Polycarbonate 1/2" Double Glaze Unit

. Acrylic Straight Wall Unit

1 = 5/8" Bronze Polycarbonate

2 = Clear 5/8" polycarb.

3 = 3/16" Bronze Acrylic

4 = 3/16" Clear Green

5 = 1/4" Bronze Polycarb.

6 = white PVC dripcap @ base & ridge

7 = Condensation/Dirt tape

. 4 "Santoprene" Seals per Rafter / Pressure Bar Cap

. White PVC Screw Cap on each Pressure Bar Cap (Also available in Brown)

. Center Glaze Section in Straight Wall Unit is bronze 1/4" polycarbonate

. Aluminum - 1" - 90 degree corner angle

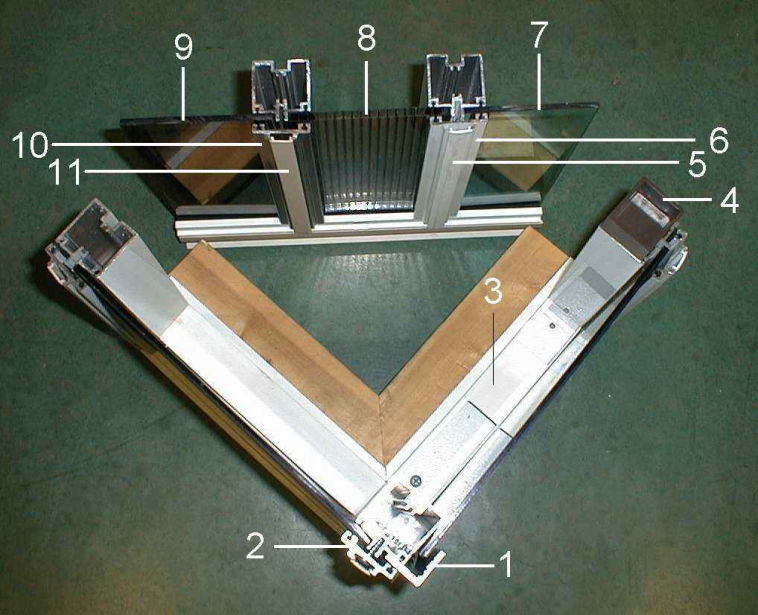

1 = 1" Angle Corner Segment

2 = Barcap @ corner

3 = PVC Dustcover (partial) on "Base & Ridge" base segment

4 = ABS Magnum plug (brown example)

5 = PVC Screw Cap cover on barcap (white)

6 = Barcap (white)

7 = 3/16" green acrylic glaze

8 = 1/4" bronze polycarbonate

9 = 3/16" bronze acrylic glaze

10 = Barcap (brown)

11 = PVC Screw Cap cover on barcap (custom beige)

. White PVC Dust Covers on Corner Unit Base (full cover + Cut-Away section)

. ABS Magnum Plug (corner unit: brown plug @ top of rafter & White plug in Base/Ridge segment)

. White PVC Base Trim / Drip Flashing

. U-Seal affixed to glaze at corner

1 = Base & Ridge (brown)

2 = PVC drip flash

3 = PVC Dust Cover (cut away section)

4 = Base & Ridge

5 = U-seal @corner glaze

6 = ABS Magnum connector plug (brown)

Aluminum

. Available in White and Brown Enamel, PLUS Custom Color "Powder Coat"

ABS Magnum Plugs Connectors

. Available in White or Brown

PVC

. Screw cap covers: (white, brown and custom colors)

. Dust Covers on "base & ridge"

. Drip flashing on "base & ridge"

Glaze

. You name it, we'll supply it.