PolyCarbonate

Awning / Solarium Glazing Materials

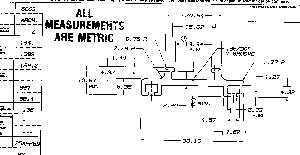

Left to

Right: (See graphic below)

- Angle

for under and over glaze @ the

Terminating front face

2(1/16" x 1.5" x

1.75")

- 1/8"

x 1" x 1' Angle

- used at all corners - see the

links to Samples

- "Base

and Ridge": used to

connect to structure @ roof and

foundation areas.

|

|

Note:

the black and white Nylon

connection plugs.

Main

rafter slip over these plugs and

locked via a screw.

- Short

Section of Rafter

- Rafter

+ Barcap which

is screwed into the

rafter every 11"

Note: the seals,

(4 in total)- 2 each per aluminum

barcap & rafter system, plus

PVC screw cap cover.

|

| |

|

|

|

|

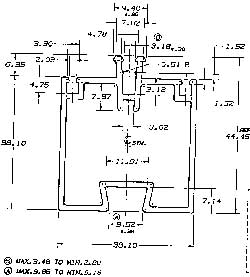

Barcap: Basically

1.5" width x 1.2" total

thickness depth.

Note:

Upper profiles receives "PVC

Screw Cap" & lower

profile receives

the cup seals (2 per Barcap

length), plus pre-drilled holes

every 11" along length for

securing barcap and glaze,

to rafter segments during

construction.

|

| |

|

|

|

|

Rafter: Both left

and right upper shoulders support

the glazing sheet with the 2 full

length seals sitting

under the glaze in respective

slots. The center channel is to

receive the screw from the

Barcap that will squeeze or lock

down the glaze, yet will still

allow the sheet to remain

alive under pressure for the

required sheet expansion and

contraction.

Note:

The underside will be able to be

slipped together to built a

double or triple rafter as

required due to some spans.

|

| |

|

|

|

|

Examples: Straight

Awning:

Rafter

centers are 24" to 26

1/8"

[

Centers are dependent on sheet

width from manufacturer (

48" to 52 1/4") ]

Note:

Cross brace at mid span and

wooden support posts + beam |

| |

|

|

|

|

Interior

view of twin wall Clear

polycarbonate glaze and white

rafter/barcap

Note:Full

length seal above and below

glaze. |

| |

|

|

|

|

Interior

view of twin wall Bronze

Tint polycarbonate

glaze and white rafter/barcap |

| |

|

|

|

|

Curved

Awning:

Bronze

Tint twin wall polycarbonate

glaze

Note:Curved

front face support posts |

Applications: Polycarbonate

twin and triple wall coextruded

Thermoglazing: Applications

requiring material which offers high

light transmission, thermal insulation,

light in weight, yet incredibly

strong, high shock resistance, flame

retardance, great economy, vandal

resistance, and

design flexibility.

- Agricultural

- Industrial

Building

- Architectural

Glazing

- Home

Improvement

Agricultural:

Greenhouse

coverings where good thermal insulation

is necessary

together with light transmission.

Industrial

Building:

Various glazing

applications, sheds, light domes,

shelters

and insulating and

light diffusing roofing.

Architectural

Glazing:

The ability to be

cold formed into arches allows design

freedom

not possible in

other glazing. Walkways, shopping

centers,

swimming pool

covers, skylights and other space

enclosures.

Home

Improvement:

Projects like

window replacements, shower enclosures,

greenhouses, partitions, light covers,

patio covers, gazebos, solariums,

carports.

| Easy

to Install: |

Polycarbonate

will not crack or split when cut

or drilled. |

| Extra

Wide Panels: |

Standard

widths of 4 ft. and length @ up

to 24 ft.

Special

Order: 6 ft. wide & up to 36

ft. length. |

| Transparent: |

Offers

up to 83% light transmission in

its clear form, also

available in bronze tint

and white translucent. |

| Lightweight: |

Weighing

just 1/8 the weight of glass.

these panels are self supporting

and do not require the extensive

structural support that a heavier

glass wall or skylight needs. |

| Highly

Flexible: |

Unlike

glass, polycarbonate can be

readily cold formed to many

bending radii, and can be

fabricated on site to precise

dimensions. The sheet can be cold

formed bent to 150 times the

thickness of the panel without

over tensioning. |

| Virtually

Unbreakable: |

Able

to withstand extreme abuse,

impact strength is 200 times greater

than glass and 10 times greater

than acrylic sheet. Maintains its

impact strength over a wide

temperature range from -40F to

+250F. |

| Saves

Energy: |

The

twin wall and triple walled

construction of these panels

gives excellent thermal

insulating values while blocking

UV transmission. |

| LightTransmission: |

White,

Bronze and clear allow light

transmission from 42% to 83%. In

addition, there is positive light

diffusion due to the rib

structure, this will provide a

certain amount of internal

privacy to the structure, plus a

critical protective screen to

young plants from burning. Sheets

carry a clear coextruded outer

surface which provides high

stability against the effects of

UV radiation and gives excellent

durability to outdoor weathering.

This unique protection insures

long term optimal quality under

intensive UV exposure. |

| Warranty: |

Backed

by a 10 year warranty on light

transmission and a 10 year

warranty against breakage caused

by hail |

|